In the manufacturing industry, many mechanical equipment require cooling systems to maintain their normal operating temperature. Yanmar pumps can be used to deliver coolant to help machines dissipate heat and prevent overheating.

WORK WITH US TO GET

THE NECESSARY SUPPORT YOU NEED

Jinrui Pump industry sales network all over the big cities in the

country, and exported to Europe, America, Asia and other world more

than 50 countries and regions.

-

Customization CapabilitiesWe can customize products or services according to the specific needs of customers and provide customers with personalized solutions.

Customization CapabilitiesWe can customize products or services according to the specific needs of customers and provide customers with personalized solutions. -

Continuous InnovationWe constantly pursue innovation and launch new products or services that meet market needs and trends to provide a unique experience.

Continuous InnovationWe constantly pursue innovation and launch new products or services that meet market needs and trends to provide a unique experience. -

Strong Supply Chain ManagementWe provide high-quality products or services to meet customer needs and expectations and ensure customer satisfaction.

Strong Supply Chain ManagementWe provide high-quality products or services to meet customer needs and expectations and ensure customer satisfaction.

ZHEJIANG JINRUI

PUMP INDUSTRY CO., LTD.

PUMP INDUSTRY CO., LTD.

We are a manufacturer focusing on the research, development, production and sales of forklift water pumps, Yanmar water pumps, Kubota water pumps, automobile water pumps and engineering machinery water pumps.

Our products cover engine water pumps for Cummins, Toyota, Mazda, Nissan, Daewoo, Komatsu, Isuzu, Mitsubishi, Volvo, Carter, Hitachi and other series, with an annual production capacity of 500,000 sets of water pump assemblies. The company always adheres to the principle of "winning by quality, reasonable price, timely delivery and thoughtful service" to provide customers with high-quality products and services. Jinrui Pump Industry's sales network covers major cities across the country, and is exported to more than 50 countries and regions in the world including Europe, America and Asia.-

0+Industry Experience

-

0+Annual Output

-

0+Marketing Area

PRODUCT CATEGORIES

-

FORKLIFT PUMP SERIESA Forklift Pump is a crucial hydraulic component designed specifically for forklifts. It plays a significant role in ensuring the smooth and efficient operation of lifting and lowering mechanisms by converting mechanical power into hydraulic energy. This energy is then used to raise and lower loads, making it an indispensable part of forklift performance. In this article, we will explore the product features, selling points, and applications of the Forklift Pump. Product Features 1. Durability - High-Quality Materials: The Forklift Pump is manufactured using high-quality materials, ensuring long-term durability even in demanding environments. - Wear-Resistant Design: The internal components of the Forklift Pump are designed to resist wear and tear, extending the pump's service life. 2. Efficient Hydraulic Performance - High Flow Rate: The Forklift Pump ensures a consistent and high flow rate, which improves the forklift’s operational efficiency during load handling. - Optimized Energy Consumption: This pump is designed to minimize energy consumption, allowing the forklift to function more efficiently while using less fuel or power. 3. Compact Design - Space-Saving Construction: The compact nature of the Forklift Pump allows it to be easily integrated into various forklift models without taking up excessive space. - Lightweight Structure: Despite its robust performance, the Forklift Pump is lightweight, which minimizes the overall weight load on the forklift. Product Selling Points 1. Reliability - Consistent Performance: One of the key selling points of the Forklift Pump is its reliable performance under continuous use. This ensures that forklifts can operate efficiently for extended periods without interruptions. - Reduced Downtime: The Forklift Pump is engineered to minimize the risk of malfunctions, contributing to reduced downtime in forklift operations and enhancing productivity. 2. Ease of Maintenance - Simplified Maintenance Process: The Forklift Pump is designed with easy access points for maintenance, making it convenient to service or replace components when necessary. - Extended Service Intervals: Thanks to its durable construction, the Forklift Pump requires less frequent maintenance, reducing long-term maintenance costs. 3. Customizability - Multiple Variants Available: The Forklift Pump is available in various models, allowing it to be customized for different forklift types and capacities. - Flexible Integration: The pump’s design allows for easy integration into both new and existing forklift models, providing flexibility to manufacturers and operators. Product Applications 1. Material Handling - Warehouse Operations: The Forklift Pump is widely used in forklifts within warehouses to handle materials efficiently, enabling operators to lift and lower loads with precision. - Loading and Unloading: Whether it's lifting heavy pallets or transporting goods, the Forklift Pump ensures smooth and controlled load handling in industrial settings. 2. Construction Sites - Heavy Load Handling: Forklifts equipped with Forklift Pumps are often used on construction sites for moving large or heavy materials, such as bricks, concrete, or steel beams. - Rough Terrain Adaptability: The robust nature of the Forklift Pump allows it to function effectively in rough terrain environments, which is common in construction zones. 3. Manufacturing Facilities - Assembly Line Integration: In manufacturing plants, forklifts with Forklift Pumps are utilized for transporting components to and from assembly lines, making the process more efficient. - Large Equipment Movement: For industries that manufacture heavy machinery or equipment, the Forklift Pump allows for the smooth movement of these large products within the factory.VIEW MORE +

-

EXCAVATOR PUMP SERIESThe Excavator Pump Series is designed to provide reliable hydraulic power for various excavator models. These pumps are essential for driving hydraulic systems that perform critical functions, including lifting, digging, and moving heavy loads. By integrating advanced engineering and high-quality materials, the Excavator Pump Series enhances the overall efficiency and performance of excavators. Product Features 1. Robust Construction - High-Quality Materials: Each pump in the Excavator Pump Series is crafted from durable materials that can withstand the rigors of heavy-duty operations. - Sealed Design: The sealed construction prevents contamination and enhances longevity, making these pumps suitable for challenging environments. 2. Efficient Hydraulic Performance - Variable Displacement: The Excavator Pump Series features variable displacement technology, allowing for precise control over hydraulic flow, which improves operational efficiency. - Optimized Power Output: Each pump is designed to deliver optimal power output, ensuring that the excavator can perform demanding tasks with ease. 3. Compact and Lightweight - Space-Saving Design: The compact design of the Excavator Pump Series allows for easy installation in various excavator models without compromising performance. - Reduced Weight: Lightweight construction minimizes the overall weight of the excavator, contributing to improved fuel efficiency and handling. Product Selling Points 1. Reliability and Consistency - Consistent Performance: The Excavator Pump Series is engineered to provide reliable performance, even under continuous operation, ensuring minimal interruptions during work. - Long Service Life: With durable components, these pumps are designed for extended use, reducing the frequency of replacements and maintenance. 2. Ease of Maintenance - User-Friendly Design: The Excavator Pump Series features accessible components that simplify maintenance tasks, allowing for quick inspections and servicing. - Longer Maintenance Intervals: The robust design reduces the need for frequent maintenance, translating to lower operating costs over time. 3. Versatile Applications - Wide Compatibility: The Excavator Pump Series is compatible with a range of excavator models, making it a flexible choice for various manufacturers and operators. - Customizable Options: We offer customizable configurations to meet specific operational needs, ensuring that each excavator can achieve optimal performance. Product Applications 1. Construction Sites - Earth Moving Operations: The Excavator Pump Series is essential for earth-moving tasks, allowing excavators to efficiently dig, lift, and transport soil and debris. - Foundation Work: In construction projects, these pumps enable precise control for digging foundations and creating trenches, enhancing overall project efficiency. 2. Mining Operations - Material Handling: The Excavator Pump Series is used extensively in mining for moving large volumes of earth and extracting valuable resources. - Heavy-Duty Performance: These pumps support the hydraulic systems needed for heavy-duty excavating equipment, ensuring reliable operation in tough mining conditions. 3. Landscaping and Demolition - Site Preparation: In landscaping, the Excavator Pump Series assists with site preparation by providing the necessary hydraulic power for various tasks, such as grading and leveling. - Demolition Projects: The pumps facilitate the demolition of structures by powering attachments that can break down walls and remove debris.VIEW MORE +

-

KUBOTA PUMP SERIESThe Kubota Pump Series is engineered to provide efficient hydraulic performance across a wide range of applications. Designed with reliability and durability in mind, this series serves various industries, including construction, agriculture, and manufacturing. The Kubota Pump Series is renowned for its robust construction and high-quality components, ensuring consistent operation even in demanding environments. Product Features 1. Durable Construction - High-Quality Materials: Each pump in the Kubota Pump Series is meticulously crafted from premium materials that are designed to resist wear and tear. This attention to quality ensures longevity, allowing the pumps to perform effectively even in demanding conditions. - Rugged Design: Whether it’s extreme temperatures, heavy vibrations, or exposure to dust and debris, these pumps are built to endure. This makes the Kubota Pump Series suitable for heavy-duty applications, ensuring consistent performance and peace of mind for operators. 2. Efficient Performance - Optimized Hydraulic Flow: The Kubota Pump Series incorporates advanced engineering techniques that improve hydraulic flow, effectively enhancing the overall efficiency of the equipment in which they are installed.This optimized flow translates into improved productivity, allowing operators to accomplish tasks more effectively while consuming less energy. - Variable Displacement Options: One of the standout features of the Kubota Pump Series is its variable displacement capabilities. This allows for precise control over hydraulic output, enabling users to tailor the pump’s performance to meet specific operational needs. 3. User-Friendly Maintenance - Accessible Components: The thoughtful design of the Kubota Pump Series facilitates easy access to key components, making maintenance tasks simpler and quicker. - Extended Service Intervals: With durable parts and an innovative design, the Kubota Pump Series is engineered to require less frequent maintenance. This extended service interval not only saves time but also reduces overall maintenance costs, allowing operators to focus on their work rather than worrying about equipment upkeep. Product Selling Points 1. Reliable Performance - Consistent Output: The Kubota Pump Series delivers reliable performance under various conditions, ensuring equipment operates smoothly. - Proven Technology: Backed by years of engineering expertise, the Kubota Pump Series employs proven technology for dependable results. 2. Versatile Applications - Wide Compatibility: The Kubota Pump Series is compatible with various machinery and equipment, making it a versatile choice for different industries. - Customizable Configurations: We offer customizable options to tailor the Kubota Pump Series to specific needs, enhancing its adaptability across applications. Product Applications 1. Construction - Heavy Machinery: The Kubota Pump Series is widely used in heavy machinery for tasks such as excavation, lifting, and material handling, providing the necessary hydraulic power. - Site Equipment: It is also utilized in various site equipment, ensuring that hydraulic systems operate efficiently for construction activities. 2. Agriculture - Irrigation Systems: The Kubota Pump Series supports irrigation systems, enabling efficient water management for crops and enhancing agricultural productivity. - Farm Equipment: This series is commonly found in various farm equipment, providing reliable hydraulic power for tractors and harvesters. 3. Manufacturing - Production Machinery: The Kubota Pump Series is integral to production machinery, facilitating various manufacturing processes through effective hydraulic systems. - Material Handling: In manufacturing settings, these pumps are used for material handling equipment, ensuring smooth operation during assembly and transport.VIEW MORE +

-

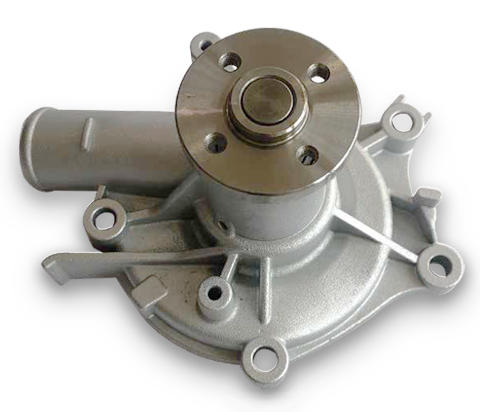

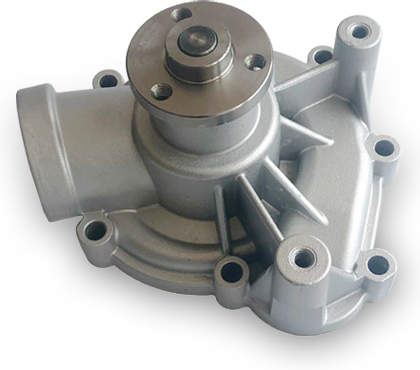

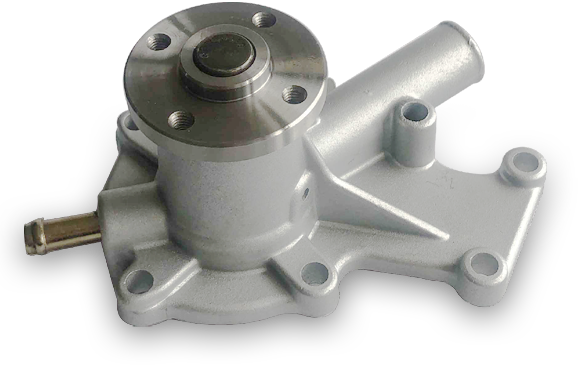

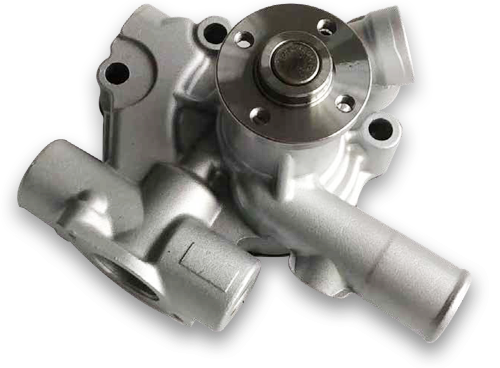

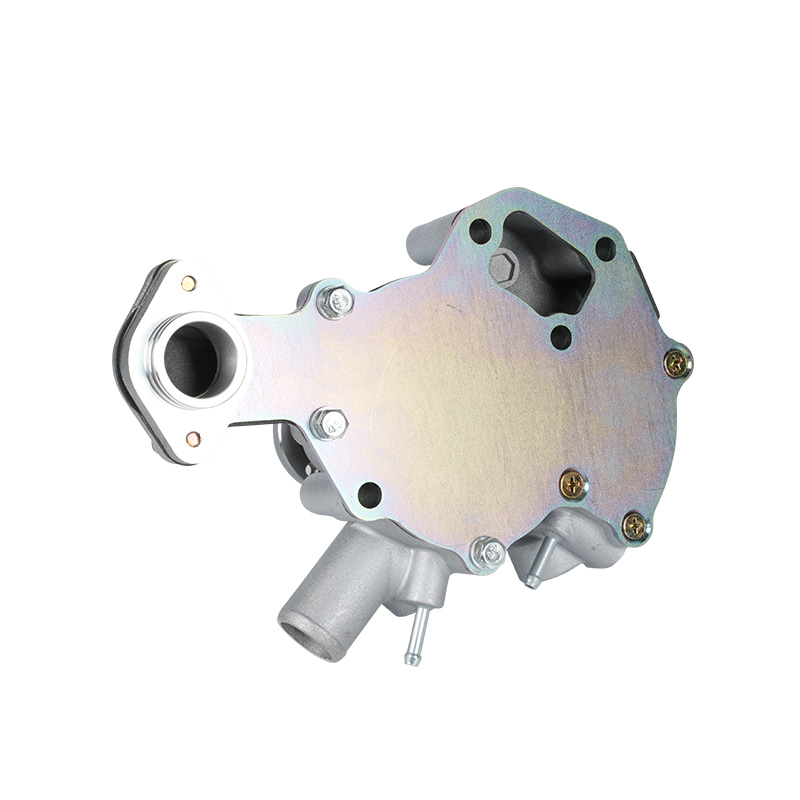

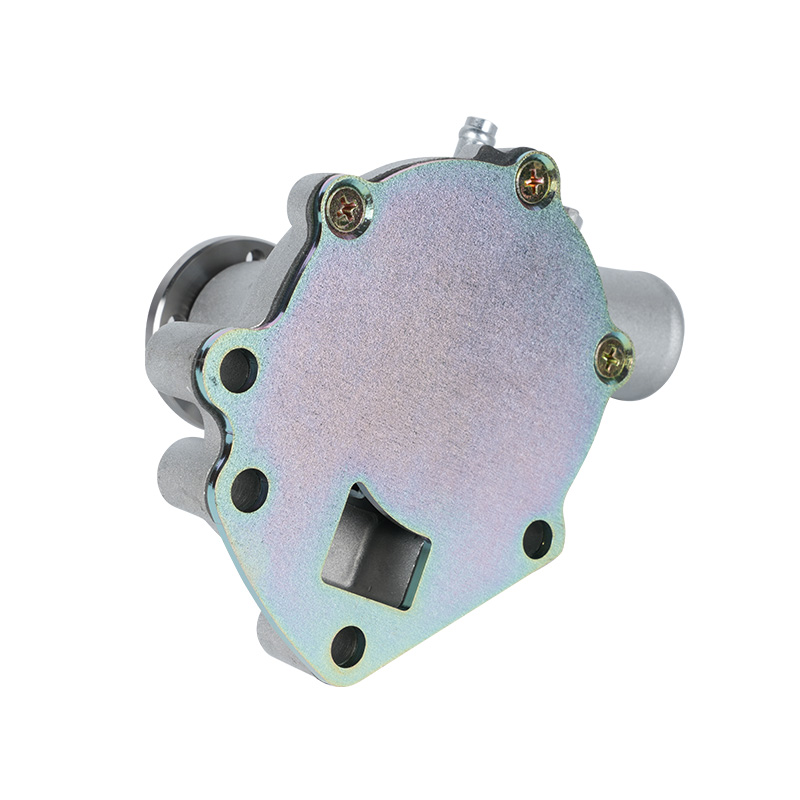

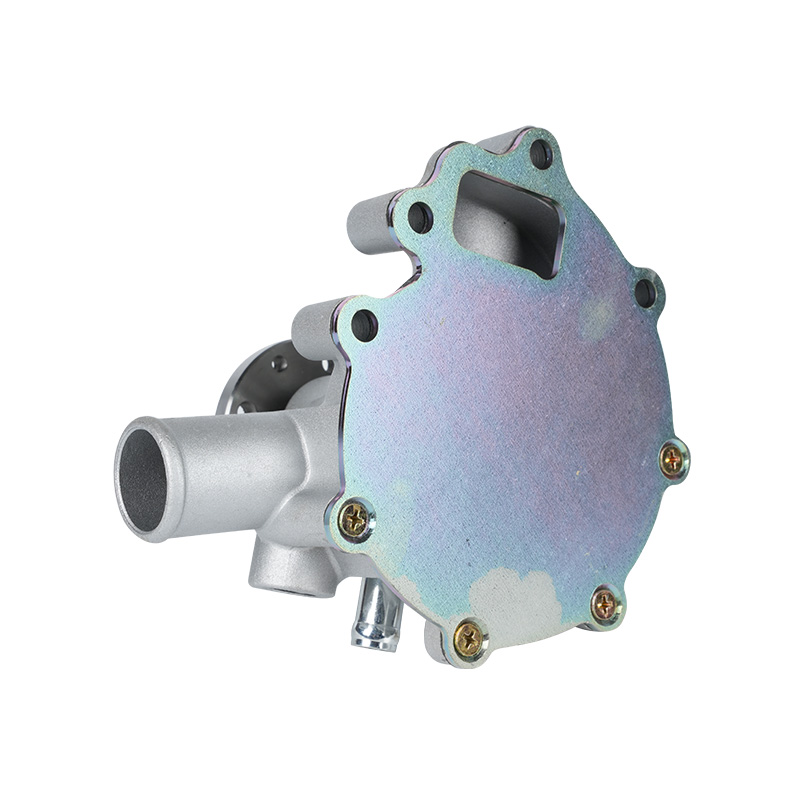

YANMA PUMP SERIESThe Yanma Pump Series is engineered to deliver reliable hydraulic performance across various industries. Known for their durability and efficiency, these pumps are designed to meet the demanding needs of applications in construction, agriculture, and manufacturing. With a commitment to quality, the Yanma Pump Series stands out for its robust construction and innovative features. Product Features 1. Durable Construction - High-Quality Materials: Each pump in the Yanma Pump Series is constructed from premium-grade materials, ensuring resistance to wear and tear. This quality enhances the longevity of the pumps, allowing them to perform effectively under demanding conditions. - Rugged Design: The rugged design of the Yanma Pump Series is tailored to withstand harsh environments, making these pumps suitable for heavy-duty applications. Their robust build ensures consistent performance, even in challenging conditions. 2. Efficient Performance - Optimized Hydraulic Flow: The Yanma Pump Series features advanced engineering that improves hydraulic flow, contributing to the overall efficiency of the equipment in which they are integrated. This enhancement allows operators to achieve better productivity in their tasks. - Variable Displacement Options: These pumps offer variable displacement capabilities, allowing precise control over hydraulic output. This feature enables users to adjust the pump's performance according to specific operational requirements, enhancing versatility. 3. User-Friendly Maintenance - Accessible Components: The design of the Yanma Pump Series prioritizes easy access to key components. This accessibility simplifies maintenance tasks, reducing downtime and ensuring that equipment remains operational for longer periods. - Extended Service Intervals: With durable components and a thoughtful design, the Yanma Pump Series minimizes the frequency of maintenance required. This leads to extended operational periods and lower maintenance costs for users. Product Selling Points 1. Reliable Performance - Consistent Operation: The Yanma Pump Series is known for its dependable performance, providing consistent hydraulic power across various applications. This reliability allows operators to trust the equipment for critical tasks. - Proven Technology: Backed by years of engineering expertise, the Yanma Pump Series utilizes proven technology that ensures efficient and reliable results in the field. 2. Versatile Applications - Wide Compatibility: The Yanma Pump Series is designed to be compatible with various types of machinery and equipment, making it a versatile choice for different industries. This adaptability enhances its usability across multiple sectors. - Customizable Configurations: We offer customizable options for the Yanma Pump Series, allowing clients to select features and configurations that meet their specific needs. This flexibility enhances the pump's functionality in diverse applications. Product Applications 1. Construction - Heavy Machinery: The Yanma Pump Series is widely used in heavy machinery applications, providing essential hydraulic power for excavation, lifting, and material handling. This makes it a critical component in construction projects. - Site Equipment: It is also utilized in various site equipment, ensuring efficient operation during construction activities and contributing to overall productivity on the job site. 2. Agriculture - Commonly found in various farm equipment, the Yanma Pump Series provides reliable hydraulic power for tractors and other agricultural machines, facilitating essential farming operations. 3. Manufacturing - Production Machinery: In manufacturing environments, the Yanma Pump Series is integral to production machinery, providing the hydraulic power necessary for various manufacturing processes. - Material Handling: The pumps are also used in material handling equipment, ensuring smooth operations during assembly and transport within manufacturing facilities.VIEW MORE +

RECOMMENDED PRODUCTS

INDUSTRY SOLUTIONS

Pumps are mainly used to transport liquids, including water, oil,

chemical liquids, etc. The main application areas are agricultural

irrigation, urban water supply, industrial production, construction and sewage treatment.

NEWS AND FAQ

Follow JINRUI trends in real-time and control the development trajectory of the industry.

- Company News

- Industry News

FAQ

MORE +

-

QWhat is your company's production capacity?A

The annual production capacity is 500,000 sets of water pump assemblies.

-

QWhat products can you provide?A

We mainly produce forklift water pumps, Yanmar water pumps, Kubota water pumps, automobile water pumps and construction machinery water pumps.

English

English 中文简体

中文简体